H46 Series Clamp Double Flap Swing Flange Check Valve

The clamp check valve is suitable for nominal pressure PN1.0MPa~42.0MPa, Class150~2500; Nominal diameter DN12~1200mm, NPS1/2~48: the working temperature of -196~540℃ of various pipes, used to prevent the backflow of the medium. Through the selection of different materials, it can be applied to water, steam, oil, nitric acid, acetic acid, strong oxidizing medium and urea and other media.

All products will be guaranteed against defects in workmanship and materials for a period of one (1) year from the date of acceptance. Defective meters or parts discovered within this period shall be replaced without charge upon return to the HBM Meters.

Standards and specifications

1, Design and manufacturing :API 594, API 6D, JB/T 8937:

2, structure length:API 594, API 6D, DIN 3202, JB/T 8937;

3, pressure-temperature rating :ANSIB 16.34, DIN 2401, GB/T 9124, HG 20605, SH 3406, JB/T74;

4, test and inspection :API 598, JB/T 9092:

5, pipe flange; JBT 74~90, GB/T9112~9124, HG20592~20635, SH 3406, ANSIB 16.5, DIN 2543~2548, GBT 13402, AP1 605,ASME B 16.47.

Structural characteristics

Structural characteristics

1, the structure length is short, its structure length is only 1/4 to 1/8 of the traditional flange check valve;

2, small size, light weight, its weight is only 1/4 to 1/20 of the traditional flange check valve;

3, and valve closing fast, water hammer pressure is small: 4, horizontal pipe or vertical pipe can be used, installation; 5, smooth flow channel, low fluid resistance;

6, sensitive action, good sealing performance:

7, the disc stroke is short, the valve closing impact is small;

8, the overall structure, simple and compact, beautiful shape:

9, long service life, strong reliability.

|

Structural form

|

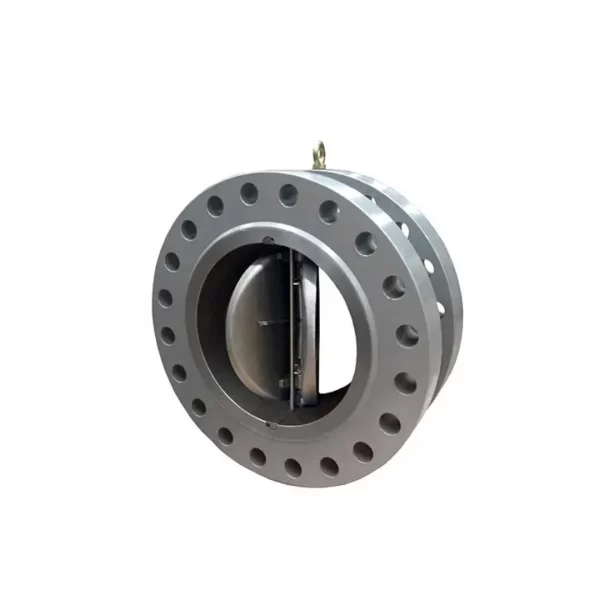

Type H46 Clamp double flap swing flange check valve

|

|

Water hammer pressure

|

Small, short disc stroke, and spring assisted closing, closing speed fast

|

|

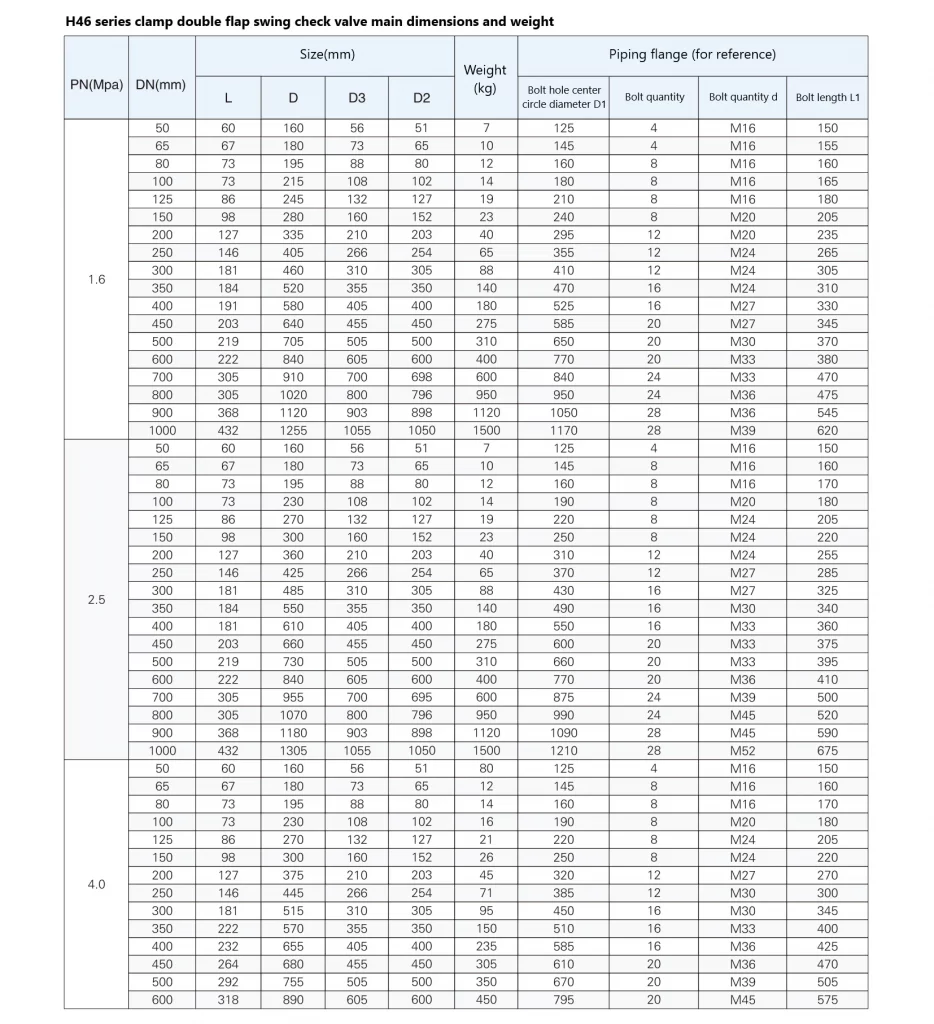

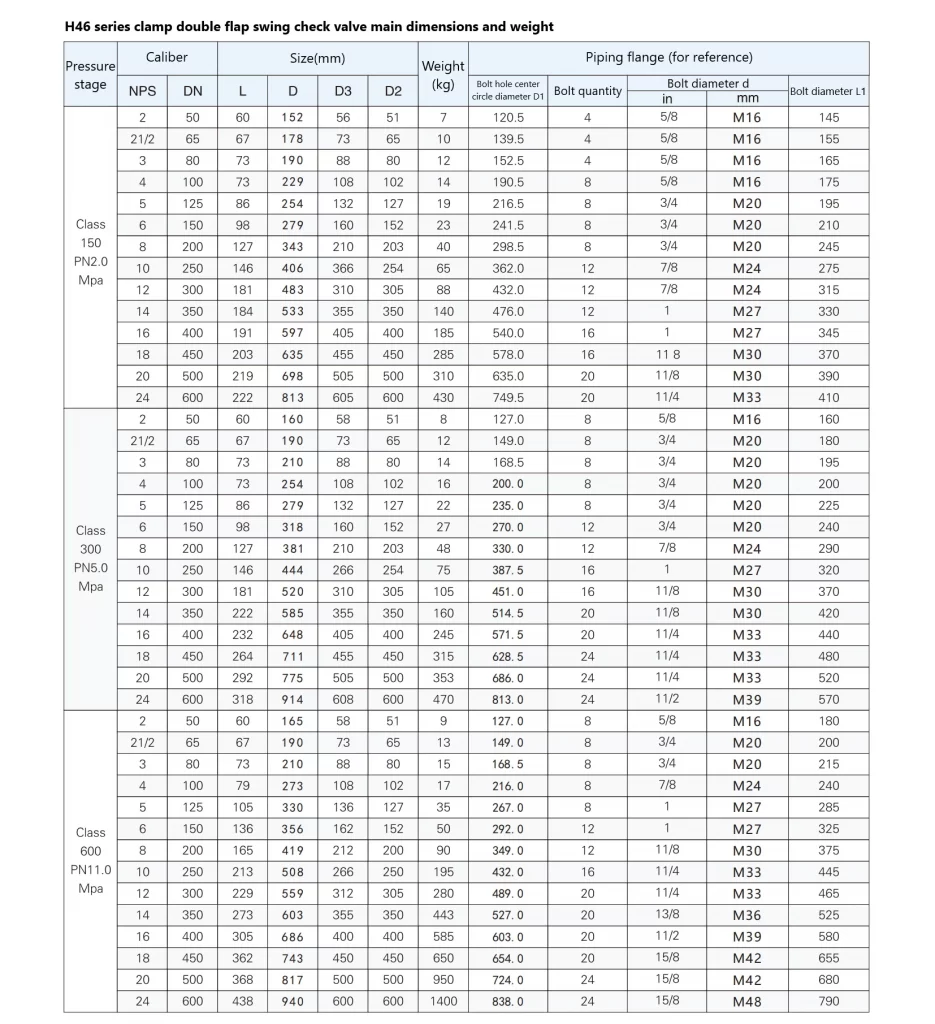

Size and weight

|

The structure is very short in length, small in size and light in weight, which brings great convenience to the installation,handling, storage and pipeline layout of the valve, and can save a lot of materials and reduce the cost

|

|

Fluid resistance

|

Small, the fluid resistance coefficient is 2.6~2.7, with the increase of valve diameter, the fluid resistance coefficient decreases

|

|

Install

|

Can be installed horizontally or vertically, light weight, no need to set a support for the valve

|

|

Opening pressure

|

Very small, the disc can be fully opened at a small pressure difference

|

|

Reliability

|

The valve is the whole structure, simple and compact, the impact force is small when the valve is closed, the water hammer pressure is small, the valve life is long and the reliability is high

|