Gray iron case removable horizontal flange industrial water meter

Measuring the volume of cold (hot) water passing through the pipeline.water meter is used for irrigation,municipality etc

A flange is a connecting profile that is commonly used to connect oil and gas surface equipment. A method for providing assembly and disassembly of components. Most oilfield flanges have a bolt hole pattern that secures the joint and gasket profile to ensure a sealed pressure seal.

This type of water meter can be used for a remote reading transmission system as equipped with a built-in sensor.Measuring the volume of cold (hot) water passing through the pipeline.All meters will be guaranteed against defects in workmanship and materials for a period of one (1) year from the date of acceptance.Defective meters or parts discovered within this period shall be replaced without charge upon return to the HBM Meters.

Operation mode: mechanical 、pulse output、 remote transmission RS485

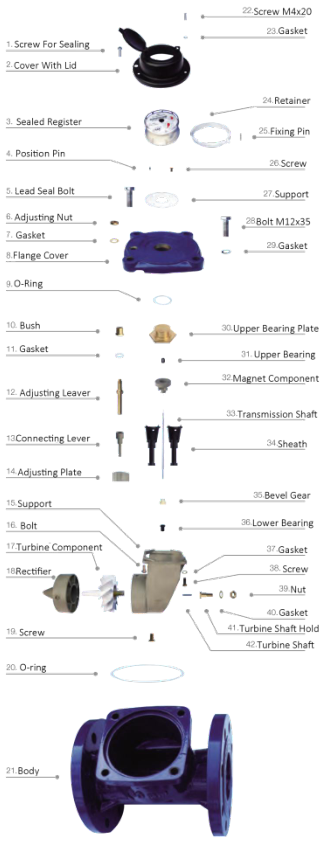

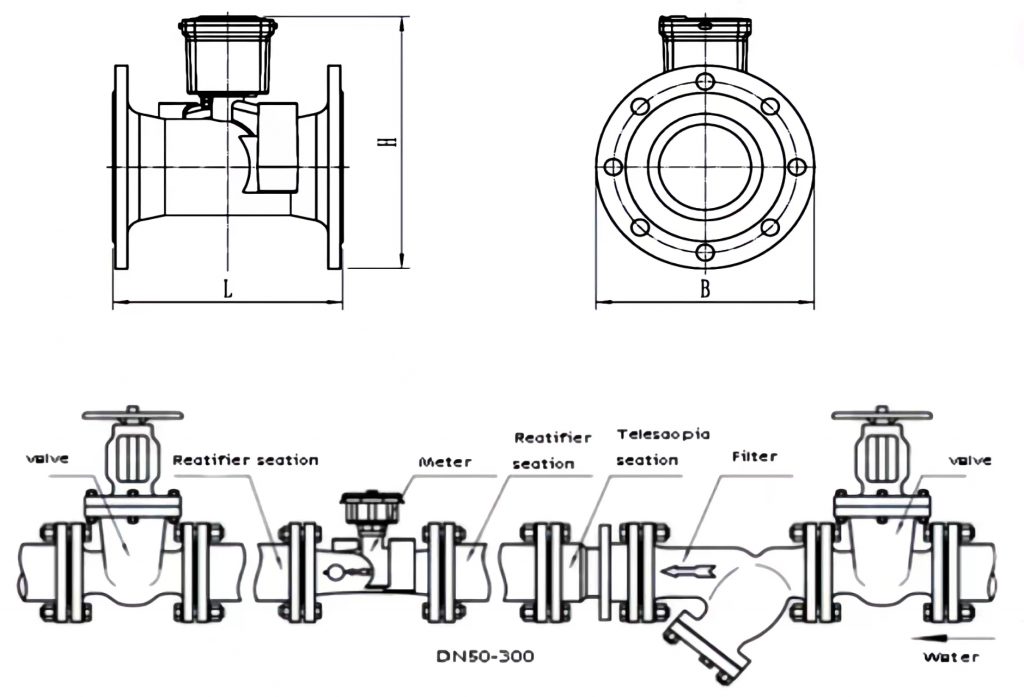

Application Exploded View

–Measuring the volume of cold (hot) water passing through the pipeline

Feature

–Removable element structure, easy installation and maintenance,

Register for universal use within this range detachable without

Removing the meter from the pipeline;

–Dry-dial, Magnetic drive sensitive action, small pressure loss;

–Vacuum sealed register ensures the dial keep free from fog and

Keep the reading clear in a long term service;

–Selected high quality materials for steady & reliable characteristic;

–Technical data conform to international standard ISO 4064.

Working condition

–Water temperature: 0.1℃~50℃ for cold water meter .0.1℃~90℃ for hot water meter.

–Water pressure: PN10/16/25

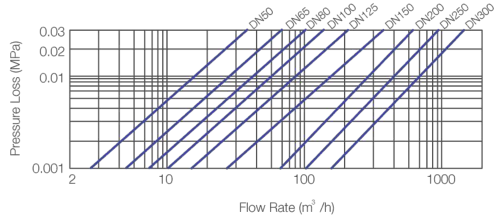

–Pressure -loss class:△p25

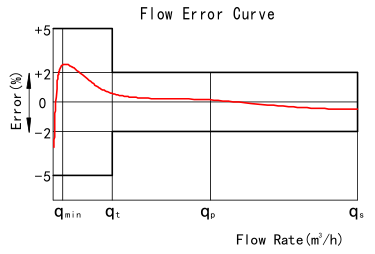

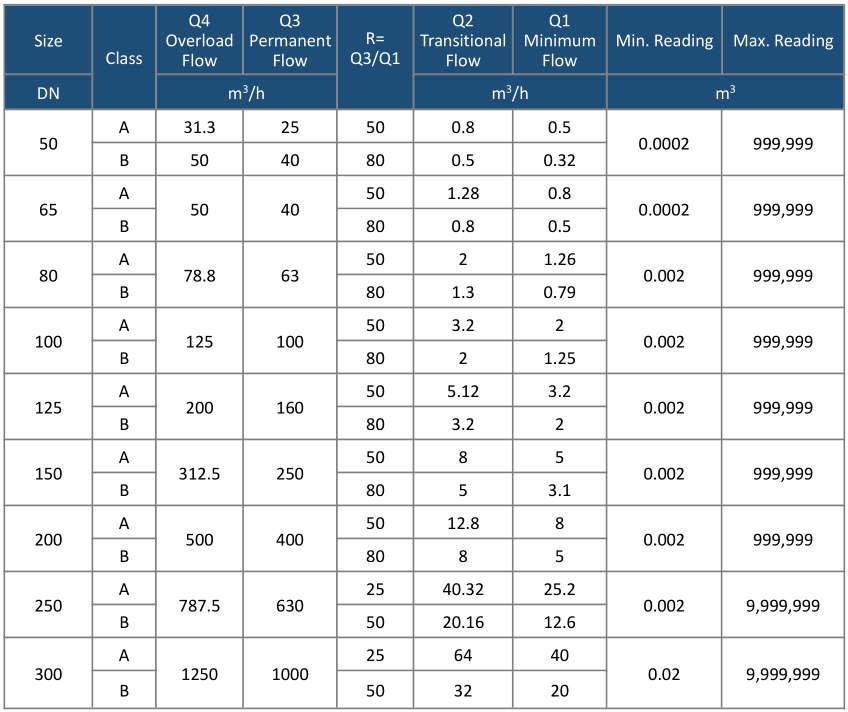

Maximum permissible errors

(1) From minimum flow -rate (Q1) inclusive to transitional flow-rate (Q2) exclusive ±5%

(2) From transitional flrow-rate (Q2) to overload flow-rate(Q4):±2% ( Hot water meter±3% )

|

Model

|

Nominal Size

|

L mm

|

H mm

|

W mm |

Connection Thread

|

Weight kg

|

||

|

Flange Outer Φ mm

|

Thread Hold center circle Φ mm

|

Thread connect Numbers

|

||||||

|

LXLC-50

|

50

|

200

|

232

|

380

|

165

|

125

|

4*M16

|

12

|

|

LXLC-65

|

65

|

200

|

232

|

380

|

185

|

145

|

4*M16

|

13

|

|

LXLC-80

|

80

|

225

|

252

|

360

|

200

|

160

|

8*M16

|

16

|

|

LXLC-100

|

100

|

250

|

262

|

380

|

220

|

180

|

8*M16

|

18

|

|

LXLC-125

|

125

|

250

|

275

|

380

|

250

|

210

|

8*M16

|

20

|

|

LXLC-150

|

150

|

300

|

325

|

420

|

285

|

240

|

8*M20

|

38

|

|

LXLC-200

|

200

|

350

|

352

|

420

|

340

|

295

|

8*M20

|

64

|

|

LXLC-250

|

250

|

450

|

470

|

660

|

395

|

350

|

12*M20

|

94

|

|

LXLC-300

|

300

|

500

|

492

|

660

|

445

|

400

|

12*M20

|

114

|

Optional Features Dials

–Plastic register, copper register and full glass register.

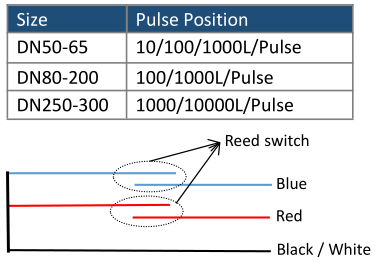

–Reed switch option.

–Flange standard can be choose.

–360 degree rotate can be choose.

–Cast iron, Ductile iron body .

–Color can be change on body and cover.

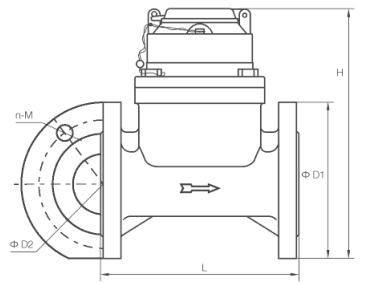

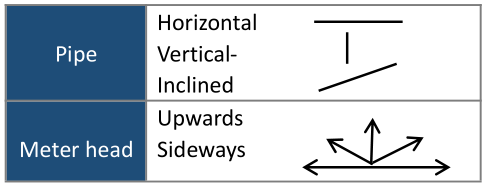

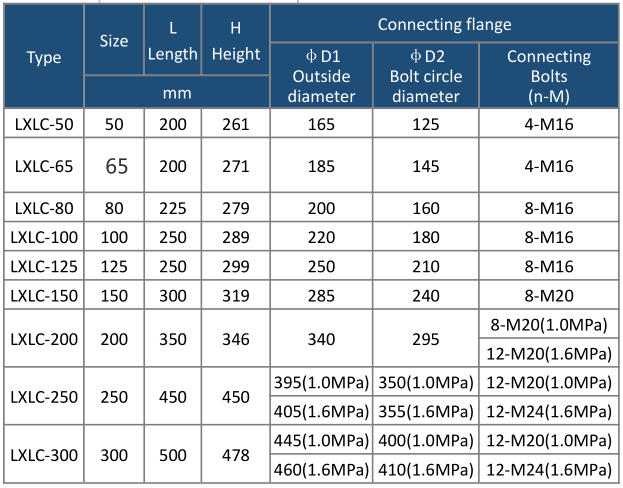

Dimensions Installation

NOTE:The flange dimension conforms to ISO7005-2:1988 standard.

Order for products of special requirements is also accepted.

Pulse Position Pressure Loss Curve

Flow Technique Specification