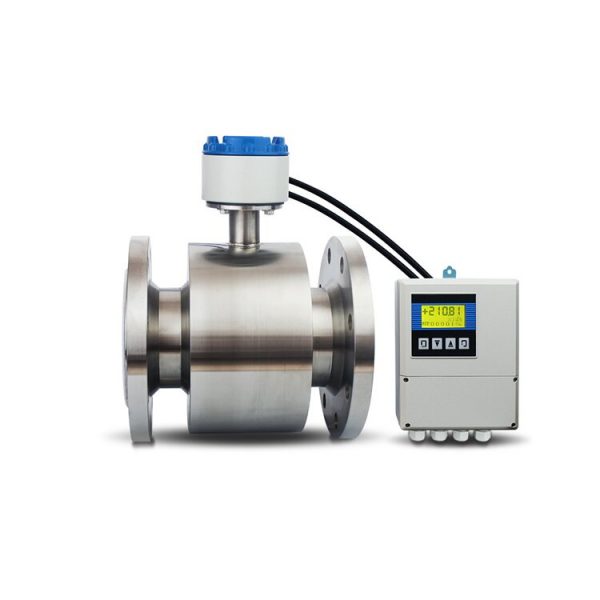

Split type electromagnetic flowmeter

Electromagnetic flowmeter can be used to measure the volume flow of conductive fluid in a closed pipeline. It is widely applied in the flow measurement and control in the fields of chemical and petroleum industry, metallurgy industry, water and wastewater, agriculture and irrigation, paper making, food and beverage industry and pharmaceutical industry, etc.

When the conductive fluid flows through the measuring tube of the sensor, the voltage signal in direct proportion to the average flow velocity of the fluid will be inducted on the electrodes. The signal is amplified and treated by the transmitter to realize various display functions.

All meters will be guaranteed against defects in workmanship and materials for a period of one (1) year from the date of acceptance.Defective meters or parts discovered within this period shall be replaced without charge upon return to the HBM Meters.

Features

▲ The measurement result has nothing to do with physical parameters such as velocity distribution, fluid pressure, temperature, density, viscosity, etc.

▲ At the scene, the range can be modified online according to the actual needs of the user.

▲ High-definition backlit LCD display, full Chinese menu operation, easy to use, simple operation, easy to learn and understand.

▲ Full digital processing, strong anti-interference ability, reliable measurement, high accuracy, flow measurement range up to 150: 1.

Working principle

Electromagnetic flow meters are flowmeters that measure flow according to Faraday’s law of electromagnetic induction. Electromagnetic flowmeters have the advantage of minimal pressure loss and a large range of measurable flow rates. The ratio of the maximum flow rate to the minimum flow rate is generally more than 20:1. The applicable industrial tube diameter is wide, up to 3 meters. The output signal and the measured flow rate are linear, and the accuracy is high. The conductivity can be measured ≥5μs/cm. Acid, alkali, salt solution, water, sewage, corrosive liquids, and fluid flow of mud, pulp, pulp, etc. However, it cannot measure the flow of gas, steam, and pure water.

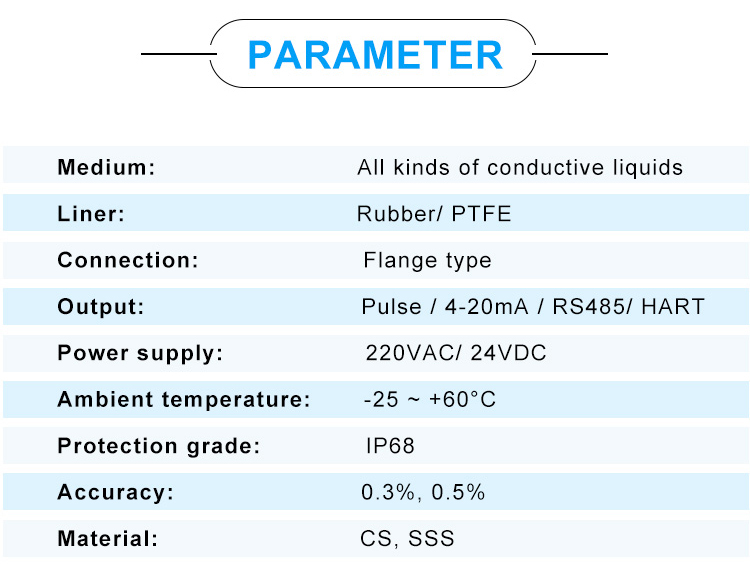

The main technical indicators:

| Nominal diameter | DN15~DN2000 |

| Accuracy | ±0.2%,±0.3%,±0.5% |

| Measurement range (flow rate) | 0.01m/s~15m/s |

| Conductivity of medium | more than 5μS/cm |

| Nominal pressure | 0.6MPa,1.0MPa,4.0MPa |

| Protection grade | IP65,IP67,IP68 |

| Electrode material | Stainless steel 316L,Hastelloy B, Hastelloy C, Titanium alloy, Tantalum alloy, Platinum-iridium alloy, Stainless steel-coated tungsten carbide and other special material . |

| Lining material | Neoprene,Polyurethane rubber,natural rubber, nitrile rubber, Teflon(PFA),Polytetrafluoroethylene(PTFE), fluorinated ethylene propylene (FEP OR F46), ceramics. |

| Connection | Flange connection [GB/T9119-2010 standard] |

| Ambient temperature | -10℃~50℃ |

| Power supply | AC220V/DC24V/DC3.6V |

| Signal output | Analog 4mA-20mA, 0Hz~ 5 KHz frequency, two alarm outputs: high limit alarm and low limit alarm |

| Communication | RS485,RS232,MODBUS,HART,PROFIBUS-DP ( OPTIONAL) |

Expression of electromagnetic flowmeter caliber:

The expression of the electromagnetic flowmeter caliber is three digits, the first two are the first and the second.

Number of caliber, the third digit means number of 0.

For example, code 150 indicates a caliber of 15 mm; code 151 indicates a diameter of 150 mm; code 152 indicates a caliber of 1500.