Gray iron case vertical removable flange industrial water meter

Measuring the volume of cold (hot) water passing through the pipeline.water meter is used for irrigation,municipality etc

A flange is a connecting profile that is commonly used to connect oil and gas surface equipment. A method for providing assembly and disassembly of components. Most oilfield flanges have a bolt hole pattern that secures the joint and gasket profile to ensure a sealed pressure seal.

This type of water meter can be used for a remote reading transmission system as equipped with a built-in sensor.Measuring the volume of cold (hot) water passing through the pipeline.All meters will be guaranteed against defects in workmanship and materials for a period of one (1) year from the date of acceptance.Defective meters or parts discovered within this period shall be replaced without charge upon return to the HBM Meters.

Operation mode: mechanical 、pulse output、 remote transmission RS485

Features:

1.No worm gear transmission mechanism, the impeller direct drive counter, transmission efficiency, low initial flow.

2.Wide range, suitable for large changes in traffic occasions.

3.Full flow detection, high precision measurement.

4.Dry magnetic structure, to ensure that the counter clean, clear display.

5.Six-digit increase in digital character wheel display readings, reading more clearly.

6.Removable measuring movement structure, easy maintenance.

7.Internal adjustable structure, to prevent unauthorized regulation.

8.Built-in stainless steel filter, the effective protection of measuring institutions.

9.High wear-resistant bearing system (gemstone bearing + high wear-resistant carbide shaft) ensures long-term product stability and reliability, significantly increasing product maximum flow.

10.Using stainless steel fasteners and epoxy resin powder to spray inside and outside the shell, to maximize antirust and extend product life.

11.Optional tamper protection cover. (To prevent users from unauthorized movement, damage or change the measurement structure, the maximum play anti-theft effect).

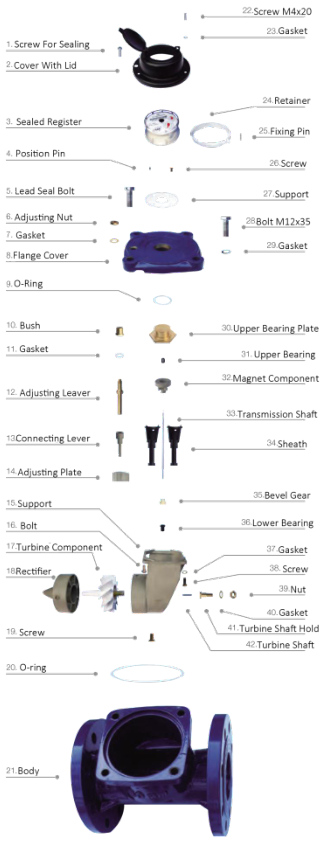

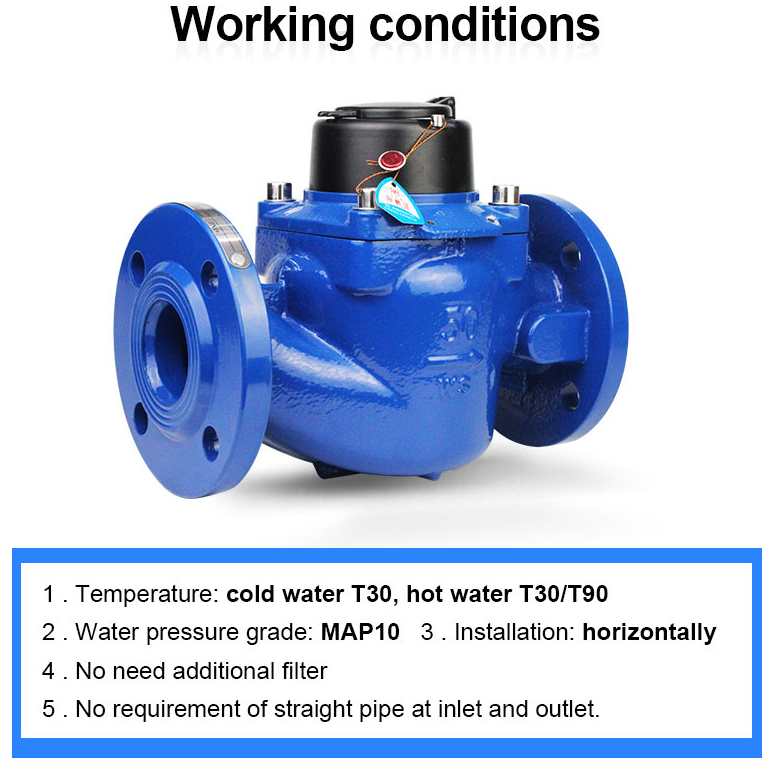

Working condition(s) Exploded View

Water temperature 0.1~30℃, Working pressure ≤1MPa.(1.6Mpa available)

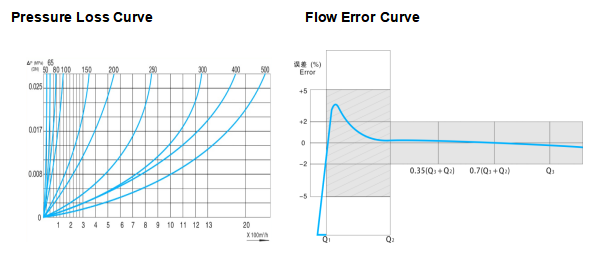

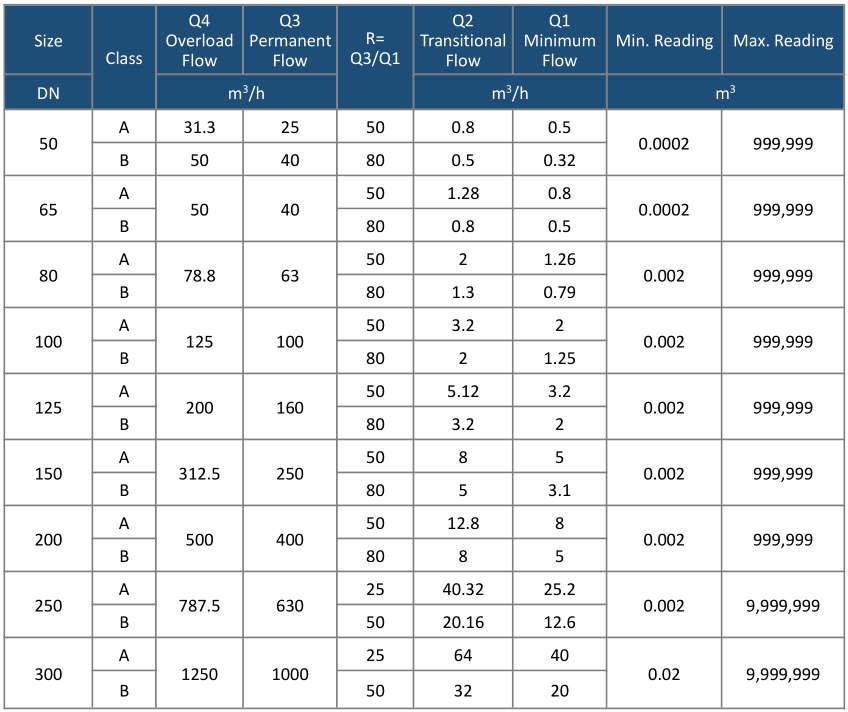

Accuracy

Low region max. allowable error: From Q1 inclusive up to but excluding Q2 is ± 5%.

High region max. allowable error: From Q2 inclusive up to and including Q 4 is ± 2%.

Applications

· For the mesuring of fluctuating flow rates

· For horizontal installation

· For cold water up to 30° C

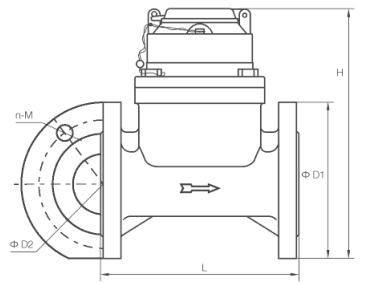

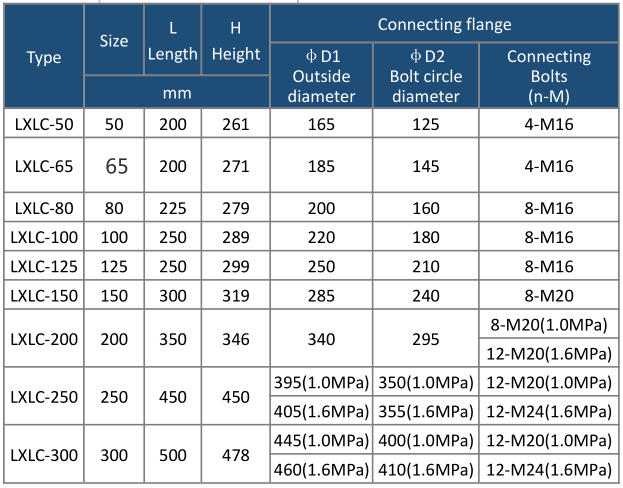

Shape and Size

|

Diameter DN

|

mm

|

50

|

80

|

100

|

150

|

200

|

|

Turndown Ratio

|

Q₃/Q₁

|

100

|

||||

|

Max Flow/Q4

|

m³/h

|

50

|

79

|

125

|

312

|

500

|

|

Nominal/Q₃

|

m³/h

|

40

|

63

|

100

|

250

|

400

|

|

Transitional/Q₂

|

m³/h

|

0.64

|

1.008

|

1.6

|

4

|

6.4

|

|

Min/Q₁

|

m³/h

|

0.4

|

0.63

|

1

|

2.5

|

4

|

|

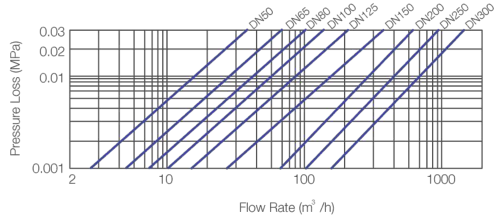

Pressure Loss Rating

|

△p

|

63

|

||||

|

Max. allowable Pressure

|

MPa

|

≤1

|

||||

|

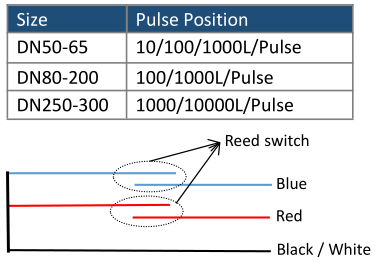

Sampling method

|

Reed switch/Magnetoresistance

|

|||||

|

Diameter

|

mm

|

50

|

80

|

100

|

150

|

200

|

|

|

Length

|

mm

|

280

|

370

|

370

|

500

|

500

|

|

|

Height

|

mm

|

228

|

290

|

306

|

445

|

564

|

|

|

Connecting

flange |

outside diameter

|

mm

|

165

|

200

|

220

|

285

|

340

|

|

inside diameter

|

mm

|

125

|

160

|

180

|

240

|

295

|

|

|

Single sided

screw data |

p

|

4*M16

|

8*M16

|

8*M16

|

8*M20

|

8*M20

|

|

|

Water meter weight

|

kg

|

15

|

29

|

31

|

78

|

120

|

|

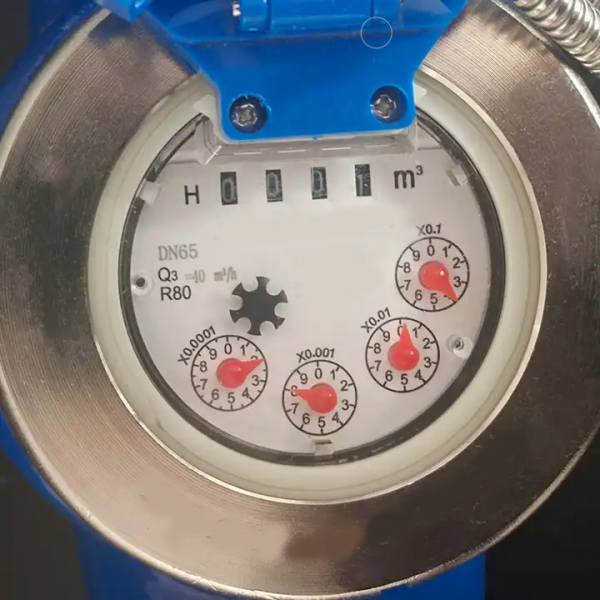

Dials

Optional Features

–Plastic register, copper register and full glass register.

–Reed switch option.

–Flange standard can be choose.

–360 degree rotate can be choose.

–Cast iron, Ductile iron body .

–Color can be change on body and cover.

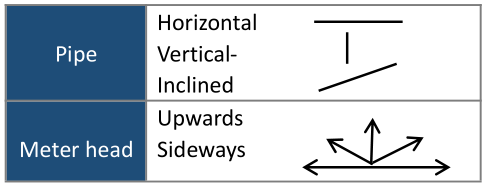

Dimensions Installation

NOTE:The flange dimension conforms to ISO7005-2:1988 standard.

Order for products of special requirements is also accepted.

Pulse Position Pressure Loss Curve

Flow Technique Specification